Über die Zeitschrift

Das RTe Journal ist eine frei zugängliche elektronische Zeitschrift, die Beiträge aus dem Fachgebiet der additiven und digitalen Fertigungstechnik – Additive Manufacturing – in deutscher oder englischer Sprache veröffentlicht. Alle eingereichten Manuskripte werden von der Redaktion auf formale Fehler geprüft und durchlaufen vor der Publikation ein inhaltliches Begutachtungsverfahren durch den wissenschaftlichen Beirat (Peer Review). Ein Anspruch auf Veröffentlichung besteht nicht.

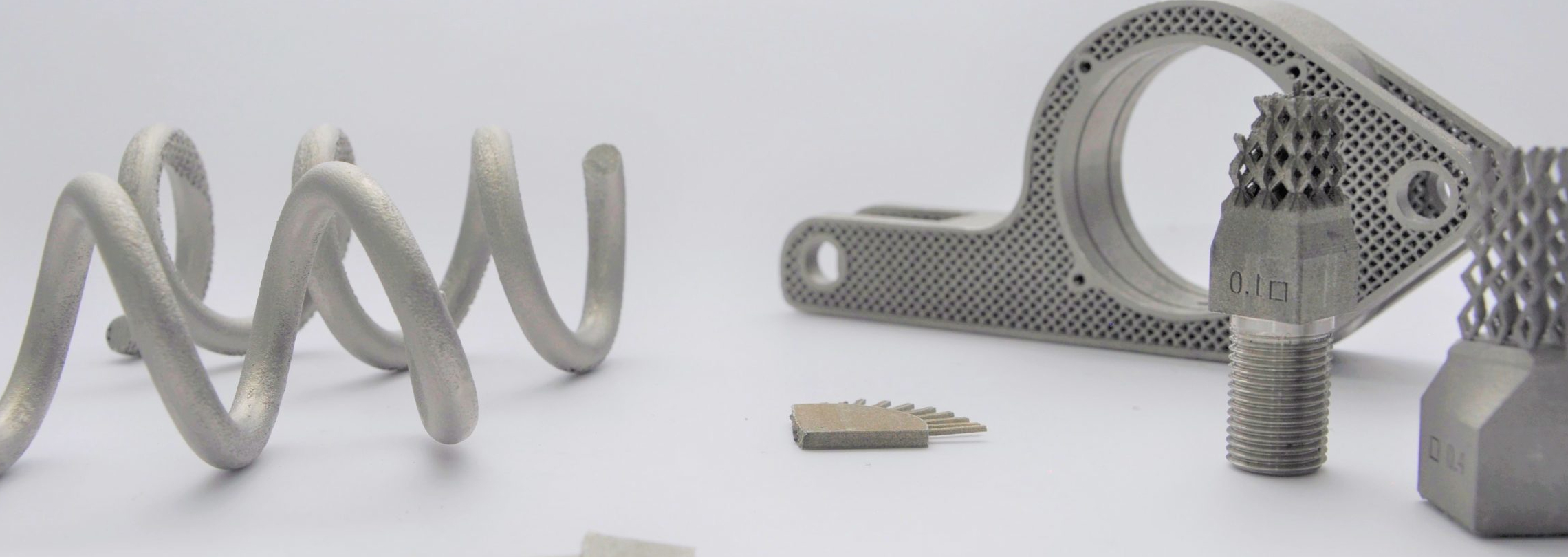

Die additiven Fertigungstechnologien haben sich in den letzten Jahren von Verfahren zur Herstellung von Prototypen hin zu industriellen Fertigungstechnologien weiterentwickelt. Additive Fertigungsverfahren ermöglichen durch den schichtweisen Aufbau und den Verzicht auf formgebende Werkzeuge zahlreiche Vorteile bei der Entwicklung und bei der Fertigung von innovativen Produkten. Aus diesem Grund werden diese Fertigungstechnologien in der Luft- und Raumfahrt, dem Werkzeugbau, der Automobilindustrie, der Energietechnik, der Medizintechnik und vielen weiteren Branchen eingesetzt, um funktionsverbesserte Bauteile für die industrielle Anwendung zu fertigen.

Die additiven Fertigungsverfahren stellen eine junge Fertigungstechnologie dar. Trotz der industriellen Anwendung existieren noch umfassende Forschungsfragen die in den nächsten Jahren durch eine grundlegende und eine anwendungsorientierte Forschung beantwortetet werden müssen, um diese Technologien langfristig und nachhaltig in physische und digitale industrielle Prozessketten implementieren zu können. Das Rte Journal hat sich zum Ziel gesetzt eine Plattform für die Veröffentlichung von angewandter Forschung mit Praxisbezug zu bieten. Innovative Ideen die gemeinsam mit der Industrie oder Forschungspartnern aus der angewandten Forschung entwickelt werden sollen durch dieses Journal eine Möglichkeit haben veröffentlicht zu werden.

RTe Journal wird herausgegeben von der Fachhochschule Aachen.